To design for a segmented turning:

- Draw the form for your turning on graph paper

- Decide on the number of layers of rings to be used.

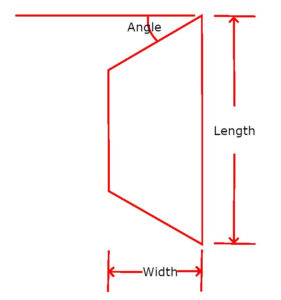

- Determine the width of the segment by the drawing

- Determine the thickness of the segment by your drawing

- Decide on the number of segments per ring.

- Use the formulas below to determine the shape of the segments and splines for each layer

Closed Ring Segment Formulas

- The length of segment formula = ((R*2*3.14)/S)*1.024

- R = radius to outside edge of turning

- S = number of segments per ring

- 1.024 = fudge factor

- Angle of end cut = (180 / N# of seg.)

Example=: 4” radius ring, 18 segments per ring

- length = ((4*2*3.14)/18)*1.024 = 1.429”

- angle = 180/18 = 10 degrees

Open Segment Ring Formula

- The length of segment formula = 70% of the closed segment length or ((R*2*3.14)/S)*1.024 *0.7

- R = radius to outside edge of turning

- S = number of segments per ring

- 1.024 = fudge factor

- Segments for an open segment turning should be between 66% and 70% of closed cut size. (The formula above would be used for a segment with 70% segment.)

- Angle of end cut = (180 / N# of seg.) * 0.7

(The above formula is for a 70% segment)

Segments Closed Cut Angles 70% of Cut Angle 66% of Cut Angle 6 30 8 22.5 10 18 12.6 11.9 12 15 10.5 9.9 15 12 8.4 7.9 14 12.86 9.0 8.5 16 11.25 7.9 7.4 18 10 7.0 6.6 20 9 6.3 5.9 24 7.5 5.3 5.0 26 6.92 4.8 4.6 28 6.43 4.5 4.2 -