Wood Turners Glossary

Cyanoacrylate adhesive glue (CA Glue) produced by the Parson Adhesives. This CA glue has extremely low viscosity and is frequently used as a finish on turned wood projects.

Cyanoacrylate adhesive glue (CA Glue) produced by the Parson Adhesives. This CA glue has extremely low viscosity and is frequently used as a finish on turned wood projects.

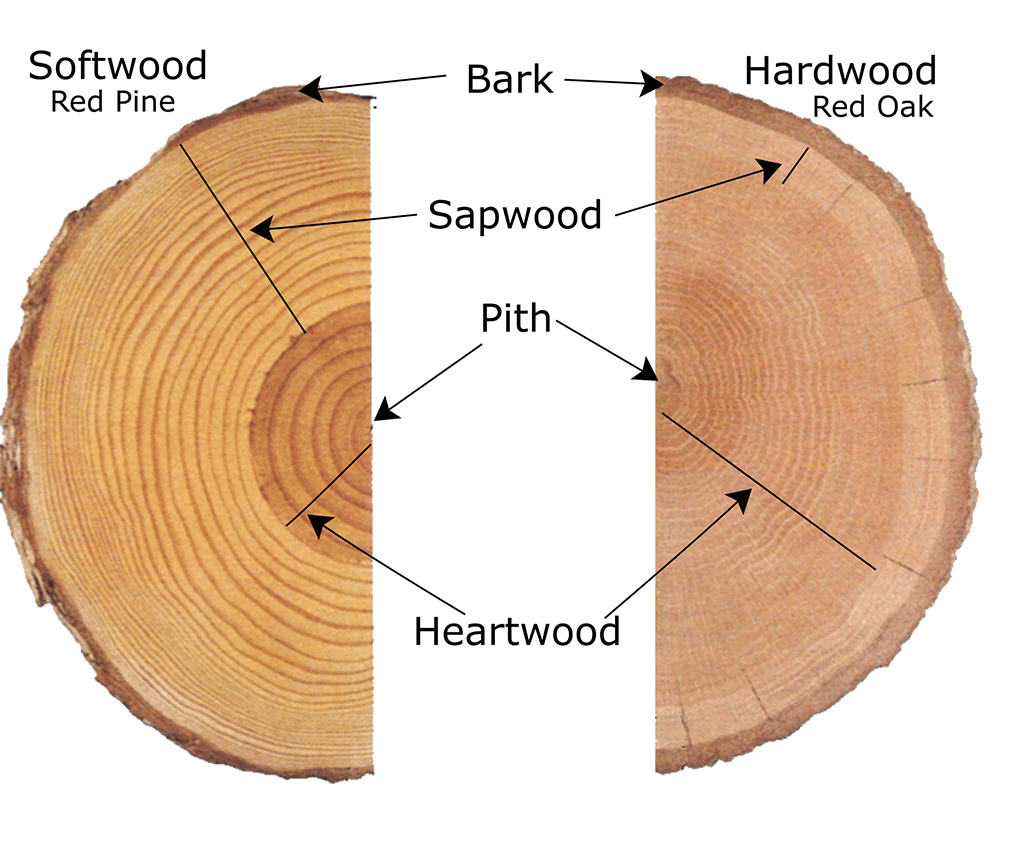

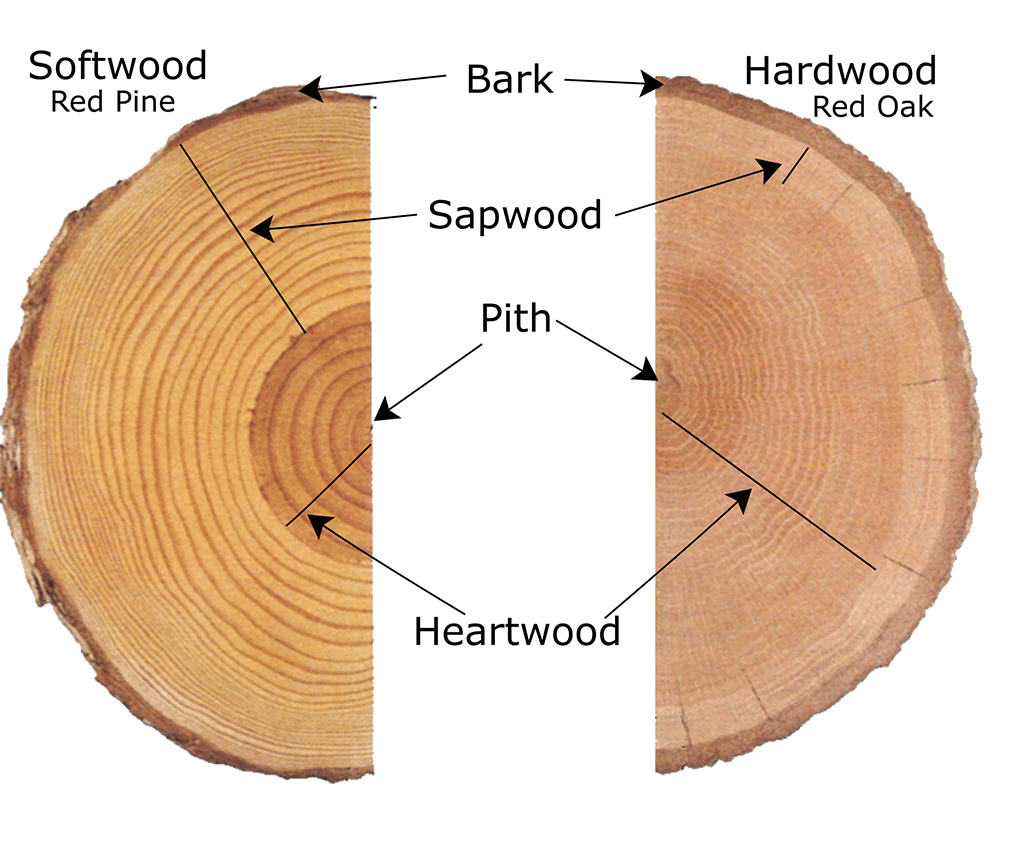

The tough outer covering of the woody stems and roots of trees, shrubs, and other woody plants. It includes all tissues outside the vascular cambium.

The tough outer covering of the woody stems and roots of trees, shrubs, and other woody plants. It includes all tissues outside the vascular cambium.

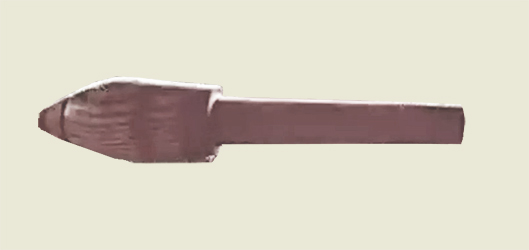

The bedan is a traditional spindle-turning tool that cuts convex shapes quickly and is capable of leaving a surface so smooth it needs only minimal sanding.

The bedan is a traditional spindle-turning tool that cuts convex shapes quickly and is capable of leaving a surface so smooth it needs only minimal sanding.

This gouge sports a blunt grind profile. It excels at handling end-grain fiber, and other difficult grains. This is used on the interior bottom of a bowl to provide a smooth finish.

This gouge sports a blunt grind profile. It excels at handling end-grain fiber, and other difficult grains. This is used on the interior bottom of a bowl to provide a smooth finish.

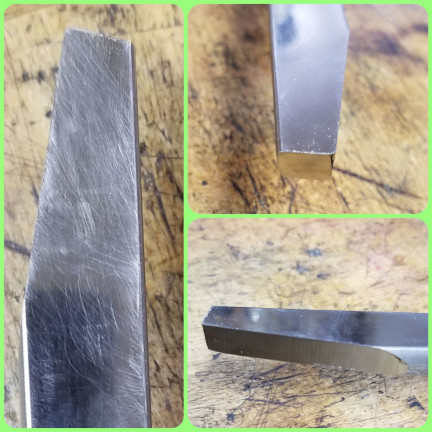

Box Scraper: used in hollowing functions, but primarily in box making. Box scrapers have a tapered cutting edge with a 70° - 85° bevel ground on the left side along with a front ground bevel of the same angle. The [cutting] bevel on the front allows for clean plunge cuts into the box with simultaneous cutting from the left cutting bevel. It also allows for quick cleanup of the vessel bottom. As with all HSS scrapers, the contact cutting point is at or just below center (<=1/8") with the tool handle elevated higher than the cutting edge(s). This is achieved by raising the tool rest to the point it allows for the scraper cutting end edge to be at center/just below (see above). Never cut on center with [any] scraper as a violent catch will happen.

Box Scraper: used in hollowing functions, but primarily in box making. Box scrapers have a tapered cutting edge with a 70° - 85° bevel ground on the left side along with a front ground bevel of the same angle. The [cutting] bevel on the front allows for clean plunge cuts into the box with simultaneous cutting from the left cutting bevel. It also allows for quick cleanup of the vessel bottom. As with all HSS scrapers, the contact cutting point is at or just below center (<=1/8") with the tool handle elevated higher than the cutting edge(s). This is achieved by raising the tool rest to the point it allows for the scraper cutting end edge to be at center/just below (see above). Never cut on center with [any] scraper as a violent catch will happen.

Cyanoacrylate adhesive glue. This glue is noted for it's quick drying behavior. Frequently referenced as crazy glue, instant glue, or other phrases. This glue has a wide range of uses, including as a finishing coat on wood working projects and quick wood glue-ups.

Blades used in conjunction with carbide turning tools. The carbide cutter heads are sharp right out of the box, and when one dulls, simply rotate it to expose a new, sharp edge. When all edges are dull, just replace the cutter head.

Blades used in conjunction with carbide turning tools. The carbide cutter heads are sharp right out of the box, and when one dulls, simply rotate it to expose a new, sharp edge. When all edges are dull, just replace the cutter head.

Carbide Turning Tools are an alternate to traditional turning tool. These tools have carbide cutter heads that are replaced when dull, rather than re-sharpened. As the tool dulls, the head is rotated to a fresh section of sharp blade. When all edges are dull, just replace the cutter head.

Carbide Turning Tools are an alternate to traditional turning tool. These tools have carbide cutter heads that are replaced when dull, rather than re-sharpened. As the tool dulls, the head is rotated to a fresh section of sharp blade. When all edges are dull, just replace the cutter head.

The process of making a resin blank in a mold of silicon or other material. Casting typically requires resin, dyes or pigments, molds, vacuum chamber or pressure pot.

The process of making a resin blank in a mold of silicon or other material. Casting typically requires resin, dyes or pigments, molds, vacuum chamber or pressure pot.

A CBN wheel is made from cubic boron nitride. This material is one of the hardest materials available, second only to diamonds. The main feature of the material is that it features a high abrasion resistance and thermal conductivity that maintains its sharp cutting edges on a turning tool.

A CBN wheel is made from cubic boron nitride. This material is one of the hardest materials available, second only to diamonds. The main feature of the material is that it features a high abrasion resistance and thermal conductivity that maintains its sharp cutting edges on a turning tool.

Any of a number of flexible scrapers used to add decorative chatter marks to turned items.

Coring systems are jigs designed to optimize the cutting of bowls out of wood. Coring systems saves the inside of the bowl that would normally be turned to shavings. As a result, multiple bowls may be turned from one blank of wood that might normally result in only one bowl.

Coring systems are jigs designed to optimize the cutting of bowls out of wood. Coring systems saves the inside of the bowl that would normally be turned to shavings. As a result, multiple bowls may be turned from one blank of wood that might normally result in only one bowl.

A center which has a Morse taper, has no bearings, does not have moving parts and fits in the head stock or tail stock. Typically, the dead center is used in the headstock as a spur drive. When used in a tailstock, it causes friction, which is not typically desired in lathes working wood.

A center which has a Morse taper, has no bearings, does not have moving parts and fits in the head stock or tail stock. Typically, the dead center is used in the headstock as a spur drive. When used in a tailstock, it causes friction, which is not typically desired in lathes working wood.

Desiccant beads are small silica gel beads that absorb moisture from air. In wood turning, these beads may be used to help dry green wood, and minimize cracking of the wood.

Desiccant beads are small silica gel beads that absorb moisture from air. In wood turning, these beads may be used to help dry green wood, and minimize cracking of the wood.

For more information, see https://www.scienceworld.ca/stories/ever-wonder-about-silica-gel/

Diamond surfaced tool used to smooth/even/flatten/clean Aluminum Oxide and other grinding wheels. Diamond dresser is not required with the CBN Grinding Wheel, which will remain clean and even.

Diamond surfaced tool used to smooth/even/flatten/clean Aluminum Oxide and other grinding wheels. Diamond dresser is not required with the CBN Grinding Wheel, which will remain clean and even.

If you use a downhill cut, you are using your skew, bowl gouge or general tool in a manner that the lower fibers of the wood support the upper layers of the wood during the cut. In the following animation, you see that the lower layers support the cut as the gouge moves down the slope.

If you use a downhill cut, you are using your skew, bowl gouge or general tool in a manner that the lower fibers of the wood support the upper layers of the wood during the cut. In the following animation, you see that the lower layers support the cut as the gouge moves down the slope.

A draw bar is a method of keeping a morse taper seated by clamping it in place. The draw bar screws into a female thread that’s often present on the small end of the morse taper, and presses on the revolving hand wheel or bearing that’s at the opposite end of the headstock spindle to the lathe bed. Since lathes differ, the draw bar isn’t something you can generally buy. But, you can make one, making the use of your lathe safer. See the video by Mike Peace for a more complete description of the drawbar and a description on how you can make a draw bar.

A draw bar is a method of keeping a morse taper seated by clamping it in place. The draw bar screws into a female thread that’s often present on the small end of the morse taper, and presses on the revolving hand wheel or bearing that’s at the opposite end of the headstock spindle to the lathe bed. Since lathes differ, the draw bar isn’t something you can generally buy. But, you can make one, making the use of your lathe safer. See the video by Mike Peace for a more complete description of the drawbar and a description on how you can make a draw bar.

A drive center, also known as a grip center, is used in the driving end of a machine (headstock). It is often used in woodworking or where softer materials are machined.

It consists of a dead center surrounded by hardened teeth, which bite into a softer workpiece allowing the workpiece to be driven directly by the center.

The duxchuck is a homemade jig defined by Jim Duxbury to allow the turning of offset-center projects. Actually, it represents an array of homemade jigs made by Jim Duxbury, as he improves and improves the design. The key to the design:

The duxchuck is a homemade jig defined by Jim Duxbury to allow the turning of offset-center projects. Actually, it represents an array of homemade jigs made by Jim Duxbury, as he improves and improves the design. The key to the design:

- Take a block of wood.

- Drill a hole the size of a tenon.

- On each side of the tenon hole, drill dowel holes perpendicular to tenon hole, edge to edge.

- Slice the wood down the face center, through the tenon hole.

- Add some aligning dowels to the dowel holes to hold the two halves together.

- Place project tenon inyour in the jig tenon hole.

- Clamp the block of wood in your chunk at the desired offset.

The Ellsworth grind is a popular grind used on bowl gouges. David Ellsworth is credited for developing the grind profile. Many believe it gives the gouge a broader range of cutting actions than a traditional grind for a bowl gouge.

The Ellsworth grind is a popular grind used on bowl gouges. David Ellsworth is credited for developing the grind profile. Many believe it gives the gouge a broader range of cutting actions than a traditional grind for a bowl gouge.

Description of an Ellsworth grinds would include a bevel of about 60 ° bevel. The wing would be about a 3/4" wing for a 5/8" diameter gouge and about a 1/2" wing for a 3/8" diameter gouge. (the wing is about 1.25 x the diameter.)

Alternate to chuck or screw chuck for hold blanks to the headstock. This is screwed to the wood being turned. Appropriate sizing of the faceplate requires the user to use a faceplate that is at least 1/3 to 1/2 the diameter of the blank being held. Warning: Do NOT use drywall screws as the attachment screws.

Alternate to chuck or screw chuck for hold blanks to the headstock. This is screwed to the wood being turned. Appropriate sizing of the faceplate requires the user to use a faceplate that is at least 1/3 to 1/2 the diameter of the blank being held. Warning: Do NOT use drywall screws as the attachment screws.

Typically, a fingernail grind would have a bevel of about 50 °, and a wing about the width of the flute.

Typically, a fingernail grind would have a bevel of about 50 °, and a wing about the width of the flute.

Description follows the approximations found at turnawoodbowl.com

This is a product used to thin and improve the flow of latex and acrylic paints, primers, stains, and textured coatings.

This is a product used to thin and improve the flow of latex and acrylic paints, primers, stains, and textured coatings.

For more information on Floetrol, see https://pittsburghsprayequip.com/blogs/news/floetrol-use-faqs

Inertial Sanding; sanding with a tool specially designed to hold a disc of sandpaper, and spin on an axis without the use of a motor. The tool relies on the fact that as a section of the disc presses against a spinning piece of wood, mounted on a lathe, the disc will spin, the sandpaper will contact the wood and sand the surface.

Inertial Sanding; sanding with a tool specially designed to hold a disc of sandpaper, and spin on an axis without the use of a motor. The tool relies on the fact that as a section of the disc presses against a spinning piece of wood, mounted on a lathe, the disc will spin, the sandpaper will contact the wood and sand the surface.

A Swept Back grind, much like the Ellsworth grind ... rather than the traditional bowl gouge grind. Many people equate the Ellsworth grind and the Irish grind. Others feel that a bevel of about 55 ° and a wing twice the shaft diameter defines the grind.

For a generic picture, see the Ellsworth Grind.

Description follows the approximations found at turnawoodbowl.com

Wooden chuck, often made as a one-off single-purpose. A jam chuck mounts in the lathe headstock and provides a friction-fit cavity or surface that the turned item can “jam” against. It can even be used to drive plates and other flat pieces, using the crest of the chuck's rim as the bearing surface.

This is a fingernail grind with extended wing. The bevel is about 50 ° with a wing about the width of the shaft diameter.

See fingernail grind for a generic picture.

Description follows the approximations found at turnawoodbowl.com

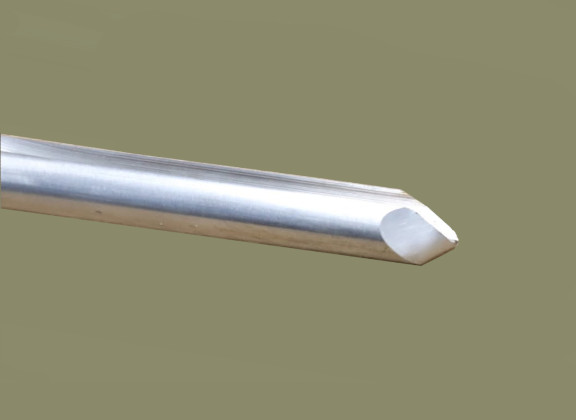

The label of the tapering of the shaft used to jam fit into mounts for headstock and tailstock. Morse tapers are described as MT1, MT2, MT3, ..., MT7. Typically, Lathes use a MT1, MT2 or MT3 taper in their headstock and tailstock.

The label of the tapering of the shaft used to jam fit into mounts for headstock and tailstock. Morse tapers are described as MT1, MT2, MT3, ..., MT7. Typically, Lathes use a MT1, MT2 or MT3 taper in their headstock and tailstock.

Food Safe finish made from 1 part Denatured Alcohol, 1 part Shellac, and 1 part Boiled Linseed Oil

Food Safe finish made from 1 part Denatured Alcohol, 1 part Shellac, and 1 part Boiled Linseed Oil

![]() OBS Studio is a free and open-source software suite for recording and live streaming. OBS provides real-time source and device capture, scene composition, encoding, recording, and broadcasting.

OBS Studio is a free and open-source software suite for recording and live streaming. OBS provides real-time source and device capture, scene composition, encoding, recording, and broadcasting.

At the very center of the tree is the pith, which is the oldest part of the tree. The pith, together with the tree's first few annual rings, is called juvenile wood. The pith area has a greater tendency to crack than the rest of the wood in a tree.

At the very center of the tree is the pith, which is the oldest part of the tree. The pith, together with the tree's first few annual rings, is called juvenile wood. The pith area has a greater tendency to crack than the rest of the wood in a tree.

Polymer Clay is a manufactured modeling compound that remains soft until cured in the oven. Polymer Clay is a combination of Polyvinyl Chloride (PVC), plasticizer and pigments. In turning, it can be used to create blanks, in combination with other materials to create turning blanks.

Polymer Clay is a manufactured modeling compound that remains soft until cured in the oven. Polymer Clay is a combination of Polyvinyl Chloride (PVC), plasticizer and pigments. In turning, it can be used to create blanks, in combination with other materials to create turning blanks.

For more information, see: https://www.claypenblanks.com/what-is-polymer-clay/polymer-clay-pen-blank-starter-guide-html

Large or small blanks cast with resin that may be turned on a lathe for interesting effects in the ultimate project.

Large or small blanks cast with resin that may be turned on a lathe for interesting effects in the ultimate project.

A variety of resins are available to produce these blanks.

The roughing gouge is used to turn your rough wood down to round. The profile and shape on the gouge are suited to taking wood off of a spindle. This is usually the first tool you use on a spindle project. DO NOT USE on cross grain cuts of a bowl.

The roughing gouge is used to turn your rough wood down to round. The profile and shape on the gouge are suited to taking wood off of a spindle. This is usually the first tool you use on a spindle project. DO NOT USE on cross grain cuts of a bowl.

A scraper does not have a critical angle for the bevel, but typically the angle would be between 60 and 70 °.

A scraper does not have a critical angle for the bevel, but typically the angle would be between 60 and 70 °.

Rubber Chucky is used in two forms. Rubber Chucky references the name of a manufacture of chuck products. Addtionally, Rubber Chucky is used to reference the generic concept of the rubber chucks that are manufactured for Rubber Chucky.

Rubber Chucky is used in two forms. Rubber Chucky references the name of a manufacture of chuck products. Addtionally, Rubber Chucky is used to reference the generic concept of the rubber chucks that are manufactured for Rubber Chucky.

Carbide carving bits for use with a rotary tool. A wide variety of bits exist for carving and may be used to decorate/detail a turned project. Saburrtooth is a brand name, perhaps we should simplify this to simply reference to a "burr," bypassing the reference to a particular brand.

Carbide carving bits for use with a rotary tool. A wide variety of bits exist for carving and may be used to decorate/detail a turned project. Saburrtooth is a brand name, perhaps we should simplify this to simply reference to a "burr," bypassing the reference to a particular brand.

A live or dead center sculpted of wood to help hold, and minimize damaging or marring the work.

A live or dead center sculpted of wood to help hold, and minimize damaging or marring the work.

Sphalted wood is any wood that has begun to decay or rot with white rot fungus. When turned, the fungus can create quite an attractive pattern and accenting in the wood.

Sphalted wood is any wood that has begun to decay or rot with white rot fungus. When turned, the fungus can create quite an attractive pattern and accenting in the wood.

Sphalted wood is not generally dangerous, despite the presence of the fungus. However, you do need to take standard precautions to prevent the dust and spores from getting into your lungs (use a dust mask). Note: The fact the wood is not typically dangerous, this does not imply that people can not have a personal allergic reactions to the inactive fungus spores contained in spalted wood.

A Spur Drive, also known as a grip center, is used in the headstock. It is used in woodworking or where softer materials are machined.

It consists of a dead center surrounded by hardened teeth, which bite into a softer workpiece allowing the workpiece to be driven directly by the center.

Also, known as the Ellsworth, or Irish grind. This labeling is descriptive of the characteristic swept back feature of the grind of the Ellsworth grind.

For a picture, see the Ellsworth Grind.

The grind typically incorporated on bowl gouges as they are provided by the manufacturer. (Bowl gouges with other grinds may be purchased, but, they are typically identified in some distinctive way, such as "an Irish Grind Bowl Gouge.")

The grind typically incorporated on bowl gouges as they are provided by the manufacturer. (Bowl gouges with other grinds may be purchased, but, they are typically identified in some distinctive way, such as "an Irish Grind Bowl Gouge.")

The Traditional grind has about a 45 ° bevel.

Description follows the approximations found at turnawoodbowl.com

A turning blank is a piece of wood that has been prepared and appropriately dimensioned to form various objects on a wood turning lathe.

If you use an uphill cut, you are using your skew, bowl gouge or general tool in a manner that the lower fibers of the wood do not necessarily support the wood. The tool can have a tendency to catch in the upper layers of the wood. In the following animation, you see that the gouge moves up in a manner that could tend to catch the upper layers of the wood. Even if you don't have a catch, this cut could result in a rougher cut.

If you use an uphill cut, you are using your skew, bowl gouge or general tool in a manner that the lower fibers of the wood do not necessarily support the wood. The tool can have a tendency to catch in the upper layers of the wood. In the following animation, you see that the gouge moves up in a manner that could tend to catch the upper layers of the wood. Even if you don't have a catch, this cut could result in a rougher cut.

Resin that is activated by exposure to UV light. Not typically used to create turning blanks, but, used to fill holes or create small accents for using in blanks. For more information, see https://acrylgiessen.com/en/uv-resin/

Resin that is activated by exposure to UV light. Not typically used to create turning blanks, but, used to fill holes or create small accents for using in blanks. For more information, see https://acrylgiessen.com/en/uv-resin/

In conjuntion with the Wolverine jig, this is a jig designed to assist in the accurate, repeatable creation of elliptic edges on spindle and bowl gouges.

In conjuntion with the Wolverine jig, this is a jig designed to assist in the accurate, repeatable creation of elliptic edges on spindle and bowl gouges.

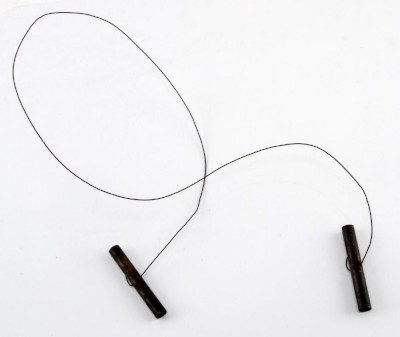

Wire-Burner; A wire connected to handles, used by heating, then wrapped around wood to create a blackened/burned ring around the wood.

Wire-Burner; A wire connected to handles, used by heating, then wrapped around wood to create a blackened/burned ring around the wood.

CA glue drying accelerator produced by Parson Adhesives.

CA glue drying accelerator produced by Parson Adhesives.  This grind is characterized by a 40 ° bevel.

This grind is characterized by a 40 ° bevel.

A center with bearings and point, typically used in the tailstock to minimize friction.

A center with bearings and point, typically used in the tailstock to minimize friction.

Southwest Association of Woodturners (swaturners.org)

Southwest Association of Woodturners (swaturners.org)

The Wolverine Grinding Jig is a jig designed to assist in the grinding sharp edges on turning tools..

The Wolverine Grinding Jig is a jig designed to assist in the grinding sharp edges on turning tools..