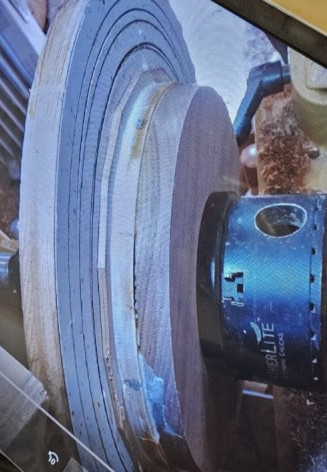

I started with a piece of laminated plywood from an old cabinet. It was only slightly larger than the round piece in the photos.

I took a 1-1/2″ x 5″ block of oak and turned it round, making sure both faces were flat and parallel. Then I drilled a 21/32″ hole in the center of one face and tapped it with a 3/4″x10tpi tap occasionally using thin CA to stiffen the oak for threading. After threading I cut a dovetail tenon on the tapped side to fit a chuck with large jaws (~ 4″). I did this to give me diversity in using the piece