I am a member of Ozark Woodturners in Mountain Home AR. A few of our members finish their turnings with CA glue. I have been envious of this practice because my lathe will not go slow enough for application. I thought for several months about this and came up with the following for applying an epoxy resin finish.

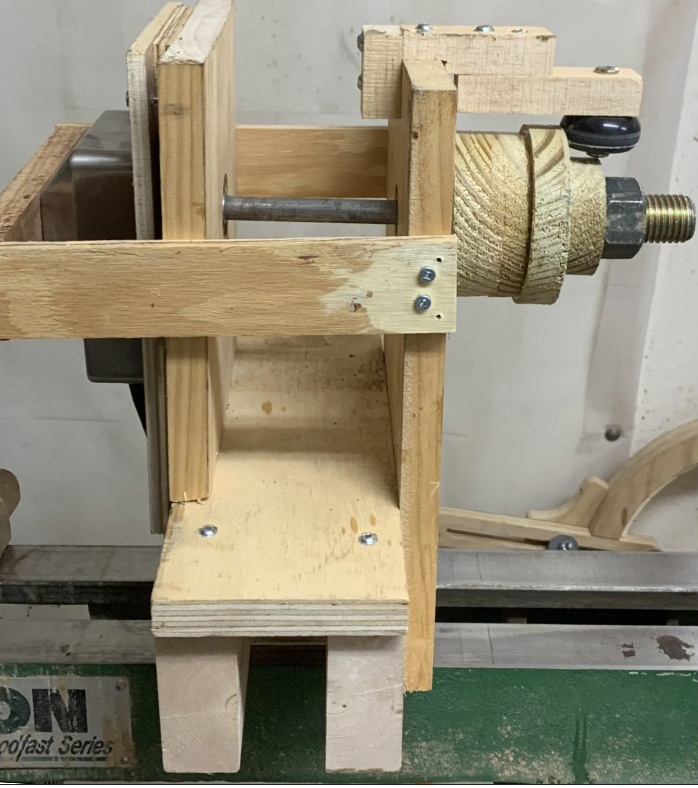

A BBQ rotisserie provides the turning at 5.5 rpm. Keeping it turning keeps the resin from pooling and allows it to spread out evenly. It is mounted on a 1/4" plywood piece and attached to a 1/2" piece and has support around it to make sure it stays in place.

A 1/2" steel rod was ground square for insertion in drive of rotisserie with bearings going through both upright supports (left).

The lateral framework (reengineer #2) is to keep the front vertical from spreading and allowing the metal rod to come out of rotisserie, causing the piece to stop spinning (seen to the left, as well).

The working end has the metal rod epoxied into a wood segment. The 1"x8TPI bolt is set into the next piece of wood.  I wanted to be able to use the jaws that the piece was turned in to connect directly to the rotisserie. The wheel at the top is to keep the entire piece from falling off in the floor (yes it happened, reengineer #1). Notice it’s a luggage wheel, the same type of wheel I used for the steady rest you can see hanging on the wall behind lathe.

I wanted to be able to use the jaws that the piece was turned in to connect directly to the rotisserie. The wheel at the top is to keep the entire piece from falling off in the floor (yes it happened, reengineer #1). Notice it’s a luggage wheel, the same type of wheel I used for the steady rest you can see hanging on the wall behind lathe.

Below is the first big piece completed with this rig. 13-1/4" x 4-1/2".