If you would like your own hardcopy of this description, click here

If you would like your own hardcopy of this description, click here

Article and graphics by Billy Burt, Sr.

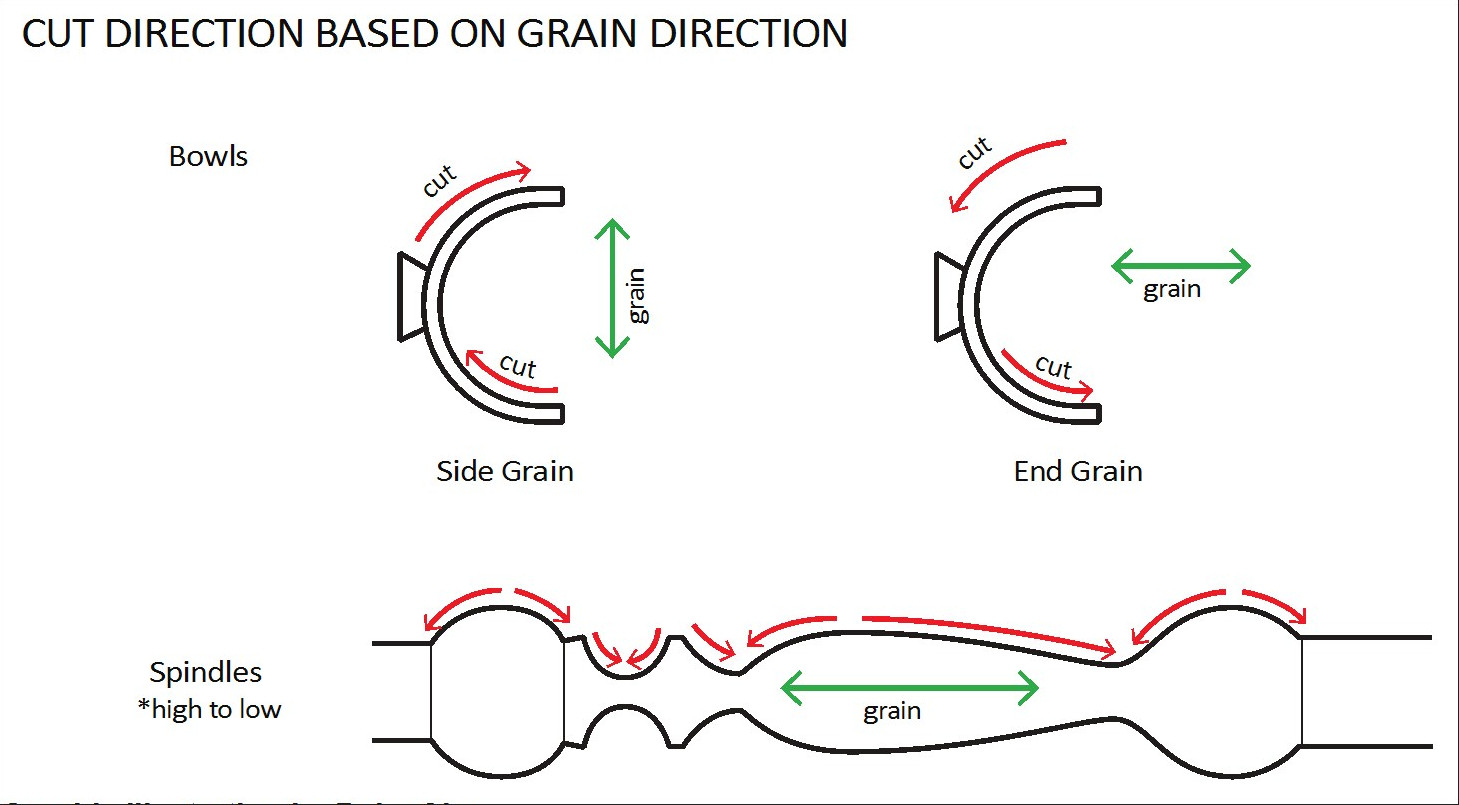

We often refer to the terms cutting uphill or downhill when we discuss woodturning; what does this mean, exactly, and how does this involve another frequently used concept, the supported or unsupported cut?

It all has to do with the fibers in the wood, and whether they are being cleanly cut or torn out. Below is an example of what we might see on the lathe:

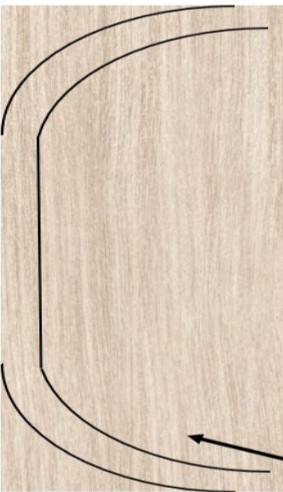

Imagine this piece of wood held between centers with the headstock on the left, tailstock on the right. Notice the grain direction. This is a spindle turning. The grain runs parallel to the bed ways from left to right. In this circumstance, we would cut in the direction shown in the next image.

Imagine this piece of wood held between centers with the headstock on the left, tailstock on the right. Notice the grain direction. This is a spindle turning. The grain runs parallel to the bed ways from left to right. In this circumstance, we would cut in the direction shown in the next image.

Notice the angle of the cut and observe the grain. We are cutting across the grain at a downward angle.

Notice the angle of the cut and observe the grain. We are cutting across the grain at a downward angle.

This is a “downhill” cut. It is also a “supported” cut, meaning that the grain being sliced is supported by the grain beneath it. A downhill cut is also referred to as cutting from “high to low.”

Cutting downhill gives us a smooth cut that, if we are presenting our tools correctly, needs little or no sanding.

You should never attempt a cut like the one shown in the next image.

Cutting against the grain is an uphill, or unsupported, cut. The wood fibers (grain) being cut are not supported by the grain above them because they are being forced up toward the surface. This causes tear out.

Cutting against the grain is an uphill, or unsupported, cut. The wood fibers (grain) being cut are not supported by the grain above them because they are being forced up toward the surface. This causes tear out.

So how does this translate to bowl turning? The next image illustrates a bowl blank on the lathe in what we refer to as straight or cross grain configuration. Notice that the grain direction runs perpendicular to the lathe bed (forward and back). Think about the uphill, downhill discussion above. Again, imagine the headstock on the left and the tailstock on the right.

So how does this translate to bowl turning? The next image illustrates a bowl blank on the lathe in what we refer to as straight or cross grain configuration. Notice that the grain direction runs perpendicular to the lathe bed (forward and back). Think about the uphill, downhill discussion above. Again, imagine the headstock on the left and the tailstock on the right. Notice that the fibers will become unsupported as we near the left side, or top of the bowl. This is why you often see turners make a cleaning cut on that side as we are “roughing” out the shape. All of our cuts on the outside of the bowl should be downhill.

Notice that the fibers will become unsupported as we near the left side, or top of the bowl. This is why you often see turners make a cleaning cut on that side as we are “roughing” out the shape. All of our cuts on the outside of the bowl should be downhill. I have heard turners refer to this as cutting uphill. Maybe because it is cutting in the opposite direction of the outside cut. Call it what you will, it is still a supported cut, because the fibers below are supporting the cut. A supported cut will always give you a better finish, If your tools are sharp and your technique is good.

I have heard turners refer to this as cutting uphill. Maybe because it is cutting in the opposite direction of the outside cut. Call it what you will, it is still a supported cut, because the fibers below are supporting the cut. A supported cut will always give you a better finish, If your tools are sharp and your technique is good.