Drying Wet Wood (2)

This video suggests some actions you can take to cause your wet wood to dry with fewer cracks.

Drying Wood for Turning Questions and Answers

If you turn green wood, it is important to protect the projet from warping and cracking. Enjoy turning the project, then, store the project in a manner that protects it until it dries (or can be dried).

This video discusses handling/protecting the green wood project.

Finishing (4)

If you want to make Shellac, or sealer, check out and explanation at https://worldwidewoodturners.org/making-shellac/.

This video explains how to make O.B. Shine Juice:

If you want to make the O.B., you’ll need the following on hand:

– Boiled Linseed Oil

– Shellac

– Denatured Alcohol

Have you found lacquer cracking on your project. Here is the discussion of the reason that appears to have caused that problem in this instance.

What Makes Lacquer Crack/p>

General (3)

Do you want some warnings about what you can and can not do with grinding wheels, well, watch this video:

Typically, you should not need to clean a CBN wheel. However, if you find yourself in need to clean a CBN wheel, perhaps this will help:

If you want greater detail on cleaning a CBN wheel, check the following video … https://www.youtube.com/watch?v=6TCFzRZpdco&t=40s at Woodturners Wonders.

Enjoy turning.

The contact list is made complicated to access to slow down the discovery and access of the list by spammers. Use the following steps carefully, inserting your name and email address to access the contact list.

To get a contact list:

- Go to the Contact page.

- Click the “Mail List Request” button at the top of the page, a form will open.

- Fill in the form with the following information:

- Name: your name here

- Email: your email address

- Subject: Captain

- Message: Please, talk to the Webmaster

- Uncheck the checked box

- Press the “Submit” button

- You will be emailed a link to a copy of the contact list. Click the link and save the list.

Miscellaneous (3)

If you are looking to put retractable casters on you lathe or bandsaw or other items in your shop, you can find incredible solutions on Youtube. Simply search for “retractable casters” or “retractable wheels” for the shop. You will find incredible solutions.

One sample is here.

Try the location at 12:09 for one idea for the lathe.

There are a number of things that can be used to stop the fogging up of your protective goggles. Try one of these things:

- Rub a dryer sheet on the goggles. (Andy Schuster)

- Rub shaving cream on the goggles. (Martin Clarkson)

- Rub any household detergent on the goggles. (Andy Schuster)

- Use ArmorAll on the goggles (John Brown)

- Use a commercial product like Rain-X on the goggles. (Jeffery Schnell)

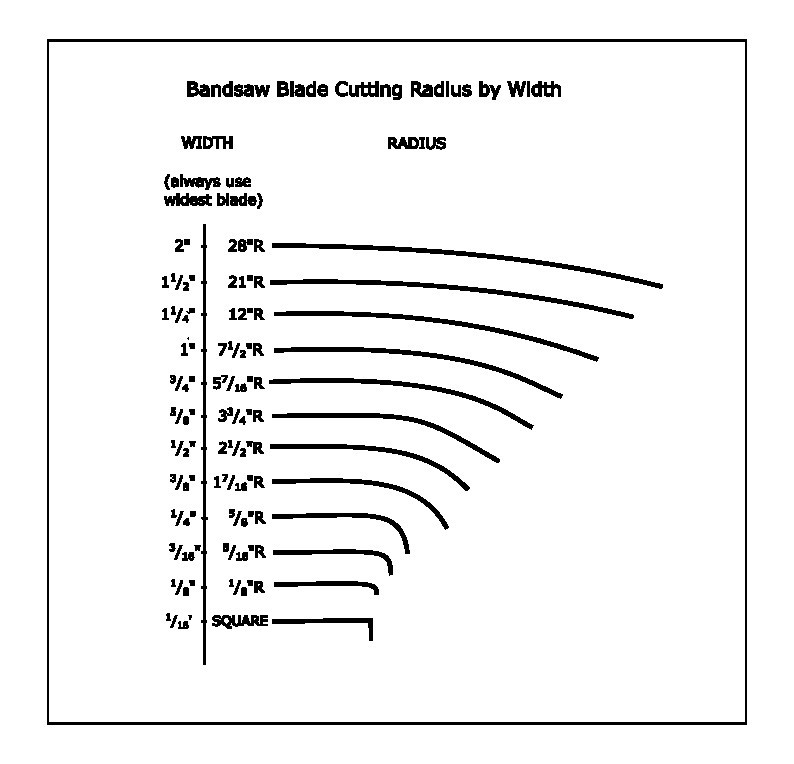

What is the tightest curve I should attempt to use for a given bandsaw blade width? Wayne Clasper offers the following chart to make it clear.

Planning Asistance (3)

We provide a tool to help you determine the size and shape of your segments … for segmented work. If you need to create segments, check out https://worldwidewoodturners.org/designing-a-segmented-project/ our page on calculating segments.

If you are creating a vessel, you may want to know what volume it will hold. There are formulas for many standard shapes, but, it is not so easy to find the volume of custom shapes.

- For a cube, the formula is:

Length x Width x Height. - For a cylinder, the formula is:

3.14159 x Radius x Radius x Height. - For a hemisphere, the formula is:

3.14159 x 2 / 3 x Radius x Radius x Radius.

But, for custom shapes, it’s not so easy. Formulas could involve use of calculus. That’s more than the average turner may want to deal with. To estimate the volume of a custom turned vessel (before turning), check out a simpler method to estimate volumes on this site.

If you need an estimate of the volume, check the following article …. https://worldwidewoodturners.org/what-volume-urn-do-i-need/

Sharpening A Gouge (6)

If your wondering, yes, you can sharpen the carbide cutters. Watch the following:

Suggested grit, 600 for sharpening carbide cutters.

Video from the Gord Rock youtube channel.

If you want to start saving the metal on your turning tools, learn how to use a diamond honing card. Use the grinder when you must, but, use the diamond honing card for quick, easy, sharpening in between major sharpening. Keep your tool sharp.

Curious about how to sharpen a skew? Check this out.

Sharpening and Using a Skew by Cap’n Eddie Castelin

Tools for You (2)

Clearly, you should use the bowl gouge that you feel comfortable with for the project you’re turning. However, if you’re new to turning, and are looking for a suggestion, you may want to start with the following suggestions. For:

- Bowls 12″ or less, consider a 1/2″ bowl gouge.

- Bowls 12″ to 14″, consider 5/8″ bowl gouge.

- Bowls larger than 14″, consider a 3/4″ bowl gouge.

While larger tools may be more efficient, bigger doesn’t always translate to better! As you grow in turning, try different sizes gouges and grinds to see what feels best in your turning.

The suggestions above are suggestions for Carter and Son Toolworks

Using a Lathe Chisel (5)

Watch this if you are curious how to do the 4 key cuts with a Skew, this is a tutorial for you.

Do you have trouble with the transition between the wall and bottom of bowls and boxes with steep edges?

Use a Bottom Feeder gouge

Do you have a question you would like answered about something in the realm of wood turning? Ask us. We would love to add your question to our FAQ, tips or HOW TO pages.Let us know or send us a copy below: