- Mirror Finish with Polymerized Tung Oil by Dane Chandler

The first step to getting a great finish on your turned vessel begins with the finish off the gouge and skew. Tool marks, tearout, and excessive sanding are a detriment to great finish and must be avoided. Begin sanding at 220 grit and finish with 320/340 grit; sanding in an oscillating ...

The first step to getting a great finish on your turned vessel begins with the finish off the gouge and skew. Tool marks, tearout, and excessive sanding are a detriment to great finish and must be avoided. Begin sanding at 220 grit and finish with 320/340 grit; sanding in an oscillating ... - Bandsaw Blade Width to Cutting Radius with Wayne Clasper

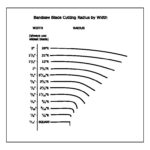

Have you ever wondered if you were using the correct bandsaw blade to cut a particular curve. Wayne Clasper would like you to know the width blade you should use to get an expected radius. To that end, Wayne offers the following chart.

Have you ever wondered if you were using the correct bandsaw blade to cut a particular curve. Wayne Clasper would like you to know the width blade you should use to get an expected radius. To that end, Wayne offers the following chart. - Making Shellac …

Folks, this article is for the woodworker that likes to use Shellac. Shellac is a great way to finish wood, but, it can have a problem. The problem being, the shelf life of an open can of shellac is about 3 years. Once a can of shellac is unsealed, it begins degrading. Three ...

Folks, this article is for the woodworker that likes to use Shellac. Shellac is a great way to finish wood, but, it can have a problem. The problem being, the shelf life of an open can of shellac is about 3 years. Once a can of shellac is unsealed, it begins degrading. Three ... - Making Danish Oil with Matt Harber

Making 2 variations of Danish Oil. Whichever formula you choose, use equal parts of the 3 part formula selected: Option 1 Clear Spar Varnish Pure Tung Oil Mineral Spirits (or one of the following paint thinner, turpentine, naptha) or Option 2 Clear Spar Varnish Boiled Linseed Oil Mineral Spirits (or one of the following paint thinner, turpentine, naptha) Matt Harber proposes using ...

Making 2 variations of Danish Oil. Whichever formula you choose, use equal parts of the 3 part formula selected: Option 1 Clear Spar Varnish Pure Tung Oil Mineral Spirits (or one of the following paint thinner, turpentine, naptha) or Option 2 Clear Spar Varnish Boiled Linseed Oil Mineral Spirits (or one of the following paint thinner, turpentine, naptha) Matt Harber proposes using ... - Designing Segmented Turning Projects with Bob Grinstead

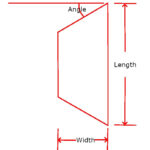

To design for a segmented turning: Draw the form for your turning on graph paper Decide on the number of layers of rings to be used. Determine the width of the segment by the drawing Determine the thickness of the segment by your drawing Decide on the number of segments per ring. Use the formulas below to determine the shape of ...

To design for a segmented turning: Draw the form for your turning on graph paper Decide on the number of layers of rings to be used. Determine the width of the segment by the drawing Determine the thickness of the segment by your drawing Decide on the number of segments per ring. Use the formulas below to determine the shape of ... - Turning Finials with Matt Harber

If you would like your own hardcopy of this description, click here Steps: Between centers, turn the tenon and base. This end will be gripped with the jawed chuck, so make sure the tenon and the underside of the base are square. Put the tenon created in step 1. into the jawed chuck. Bring up the tailstock ...

If you would like your own hardcopy of this description, click here Steps: Between centers, turn the tenon and base. This end will be gripped with the jawed chuck, so make sure the tenon and the underside of the base are square. Put the tenon created in step 1. into the jawed chuck. Bring up the tailstock ... - Microwave Drying Green Wood with Matt Harber

If you would like your own hardcopy of this description, click here This is my drying process for turned wood pieces using a microwave oven. It contains information and processes learned from several different woodturners, along with my own experiences. Note #1: Should small cracks begin to develop, I use superglue (CA glue, cyanoacrylic glue), Starbond ...

If you would like your own hardcopy of this description, click here This is my drying process for turned wood pieces using a microwave oven. It contains information and processes learned from several different woodturners, along with my own experiences. Note #1: Should small cracks begin to develop, I use superglue (CA glue, cyanoacrylic glue), Starbond ...

If you have a tips or tricks article you would like published, please let us know. We would love to publish it on our site. Let us know or send us a copy below: