If you would like your own hardcopy of this description, click here

How to drill the end of a 5/8”steel rod for a 3/8” Double ended end mill without a metal lathe

Use a drill press and align the Jacob’s chuck with the hole in the Table

Clamp a block of wood to the table

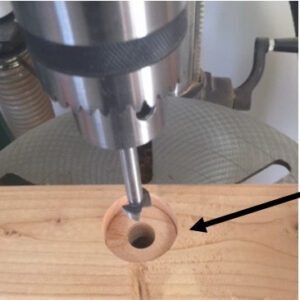

Find a forstner bit bigger than your chuck’s insert

Drill the wood with the forstner to the depth of your chuck’s insert This so the chuck will lay flat on the wood

Drill through the wood using a 5/8 drill

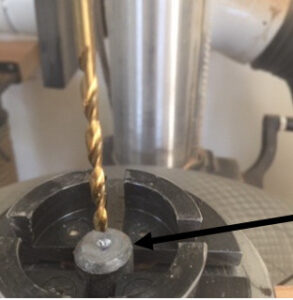

Insert the rod though the table, and the wood.

Clamp it with the chuck

Mark the start point for your drill

Taking your time and using a lot of oil drill a 1/8” pilot hole 2.5 inches deep

Again taking your time, using a lot of oil and a 3/8 drill take the hole out to final size