If you would like your own hardcopy of this description, click here

If you would like your own hardcopy of this description, click here

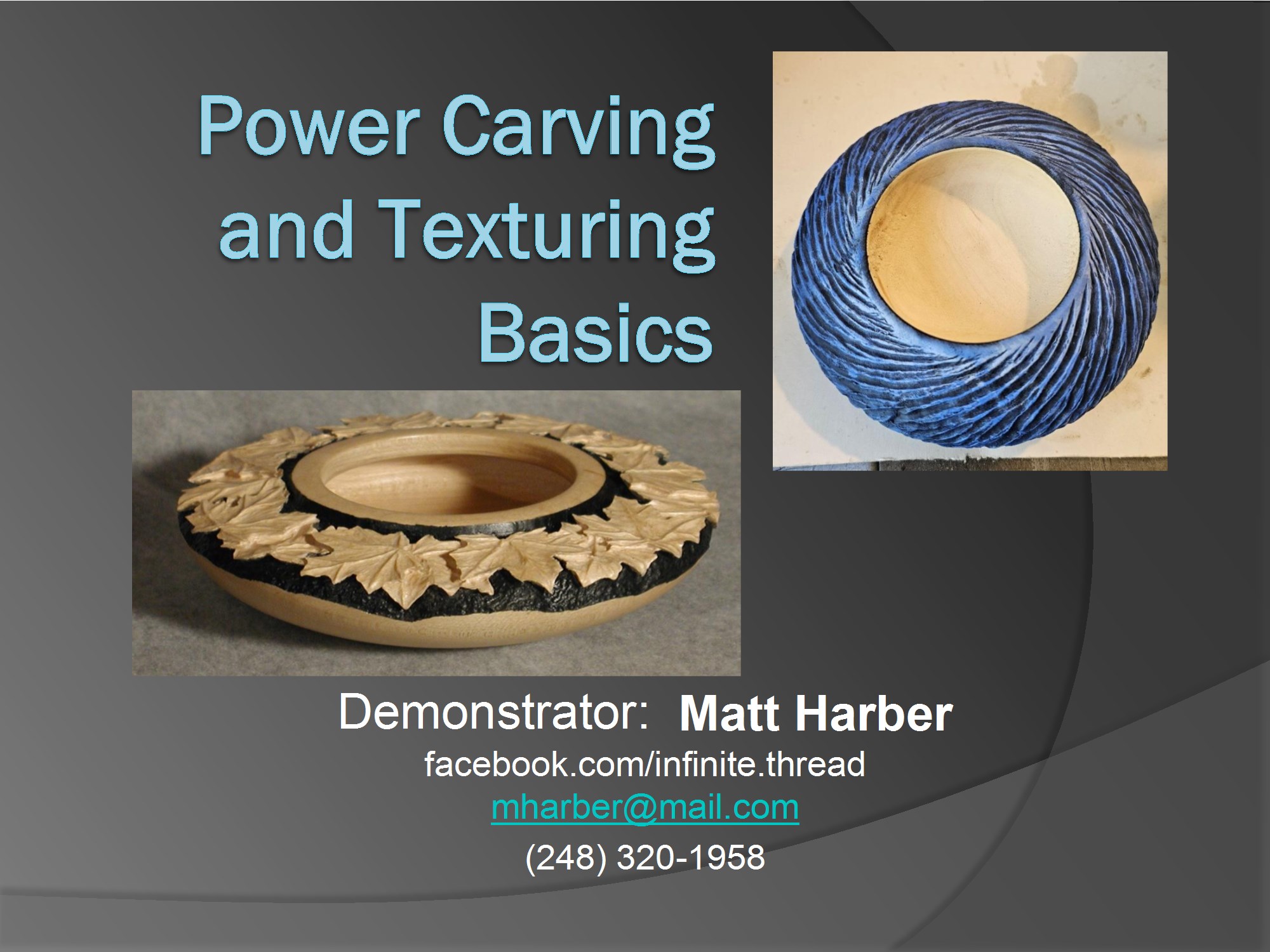

Influences:

- Dixie Biggs

- Greg Gallegos

- Nick Agar

Machines used:

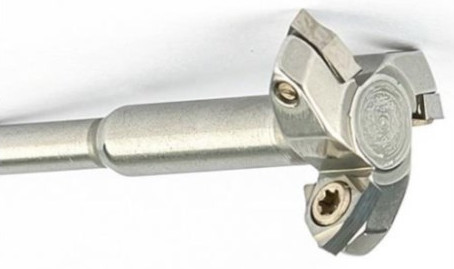

- Foredom: Strong, high torque. ¼" shaft (usually).

- Dremel (or similar rotary tool): 1/8” shaft. With proper collets, can use 3/32” and 1/16" shaft burrs. 0 – 18,000 RPM.

- Micromotor (I use Mastercarver Micro Pro Champion): 1/8", 3/32" shafts. Can also use 1/16” shaft burrs – usually dental bits, often used for piercing.

0 – 46,000 RPM.

Tools and Materials:

-

SaburrTooth.com (carving burrs – coarse [green] and fine [yellow])

- Sphere burrs, large and small

- Flame burrs

- Ball nose burrs

- MDIWoodCarvers.com (stump cutters, more)

- 21-SET35 – Rounded Cylinder Mini Stump Cutter Set (3/32" shank)

- 20-B5 – 5mm Bud Stump Cutter (3/32" shank)

- 20-S6 6mm Sphere Stump Cutter

- Amazon.com

- 3/4" radial bristle discs, 220 grit

- HarborFreight.com (1/8" diamond bit sets)

- Diamond Point Rotary Bit Set, 20-piece

- Diamond Rotary Point Set, 50-piece

- WoodWorkingShop.com (Klingspor)

- Manpa mini carving bit, 1/8" shank (triangle, round head)

Notes

- When turning a piece to carve, look at it as a canvas for your carving. Plan the contours to show your carving work.

- Round contours work a lot better for carving than sharp edges. If you plan for your carving to follow or cross a contour, it works a lot better if that contour is rounded.

- If you plan to paint and/or dry brush your carving, work to create details and surfaces that handle your planned painting. Often, these are sharp edges in the carving.

- Take your time. Take light cuts. You can always carve more wood off.

- When sanding or smoothing with diamond burrs, turn the tool speed down low. It’s pretty easy to burnish or burn the wood with diamond burrs.